A CENTURY OF PROVEN

OEM PERFORMANCE

We can help you produce prototypes and custom designs up through short runs of your products, with demanding requirements and tolerances.

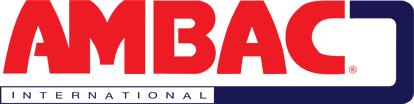

Engineering

- Product/Process

- PLM and PDM Disciplines

- Solidworks 2016 CAD

- Geometric Dimensions and Tolerancing

- Components and Assemblies

- Reverse Engineering

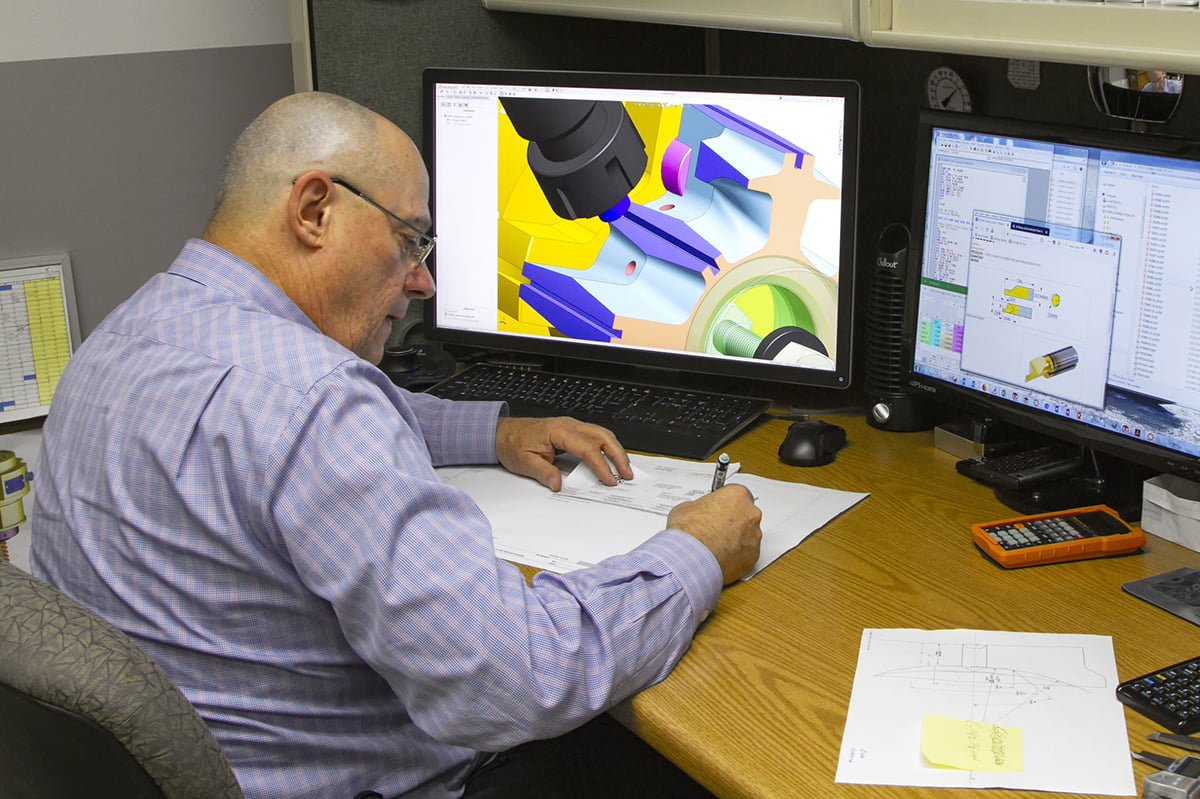

Manufacturing

- Milling, Drilling, and Turning

- CNC Verticals and Horizontals

- CNC Lathes with Bar Feed

- Cam Grinding

- Hard Turning

Grinding:

- Cylindrical

- Centerless

- Surface

Honing and Lapping:

- Sunnen Hones

- Multi-Spindle Laps

Quality

- Metrology Lab

- Gage Recall (Calibration Recall 3)

- CMM

Wide Variety of Inspection Capabilities:

- Torque, RPM

- Temperature

- Pressure, Weight

- Optic Based Inspection

- Sub Micron Length, ID, OD

- Spring Load, Rate

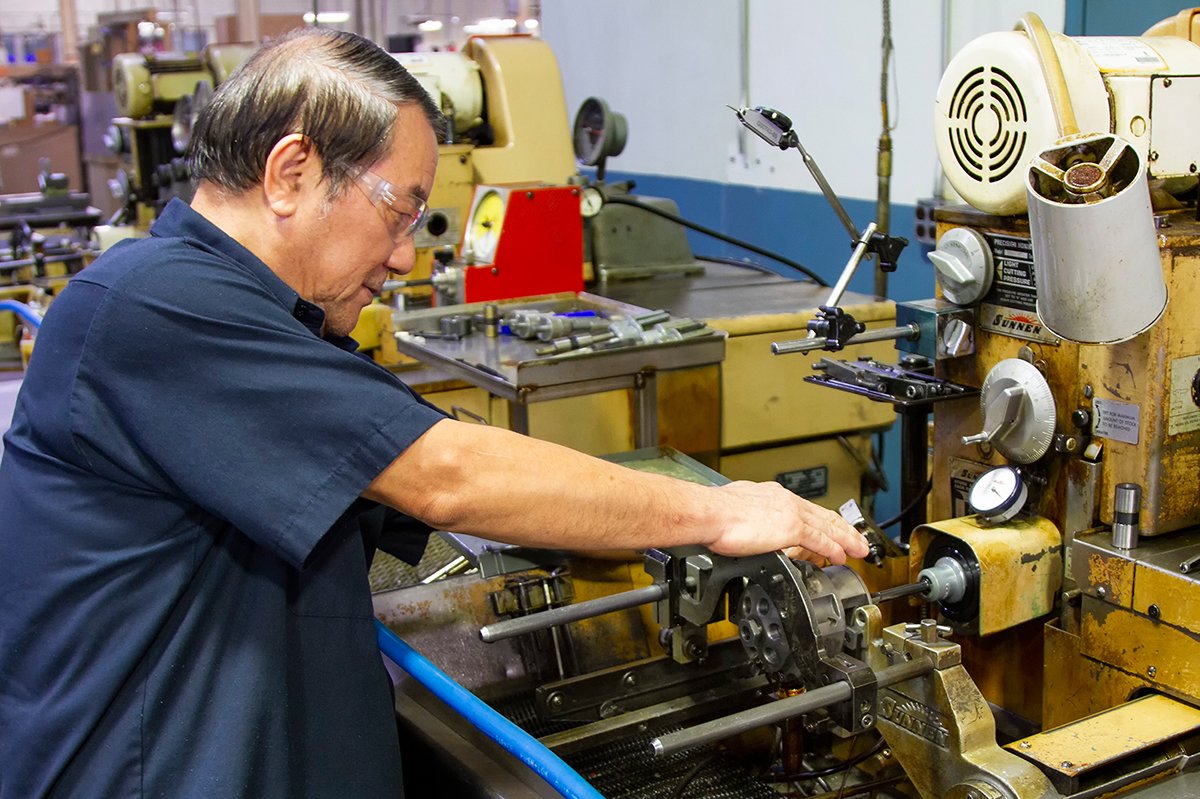

Engineering Lab

- Product Development and

- Application

- Hydraulic Testing

- Electronic Support

- Non-Destructive Testing

- Endurance, Life Cycle Testing

Metallurgical Lab

Metalography Capabilities:

- Hardness Inspection (RC, Brinell, Vickers)

- Nital Etching

- Magnetic Particle Inspection

- Microstructure Analysis

- Hardness Profiles

Measurement

- CMM

- Optical Comparators

- Micro-Hite

- Spring Tester

- Mag Particle

- Air Gaging

Welding

- MIG

- TIG

- Speciality

- Wire EDM

- Sinkers (ELOX)

- Match Grinding

Heat Treat

- Lepel and GE Induction Hardening

- Thermal Deburr

- Small Furnaces and Quench

Supply Chain

- Near Net Shape (Casting, Forgings, Extrusions, Stampings)

- Heat Treat, Plating, Painting, Components

Springs, Hardware, Fasteners

Facility

- 72,000 sq ft Facility

- Air Conditioned

- Easy Access to Interstate Highways

Controls in place for:

- Material, Tool, and Gauge Control

- USG / DoD Prime Contractor

- Scrap removal

- Active Safety Committee

- Full Tool Room

- Assembly and Test Capabilitie